Victoria Rößler

Sales Manager Filtration Line

| T: | +49 3733 55 07 421 | |

| M: | Victoria.Roessler@norafin.com | |

| LinkedIn profile | |

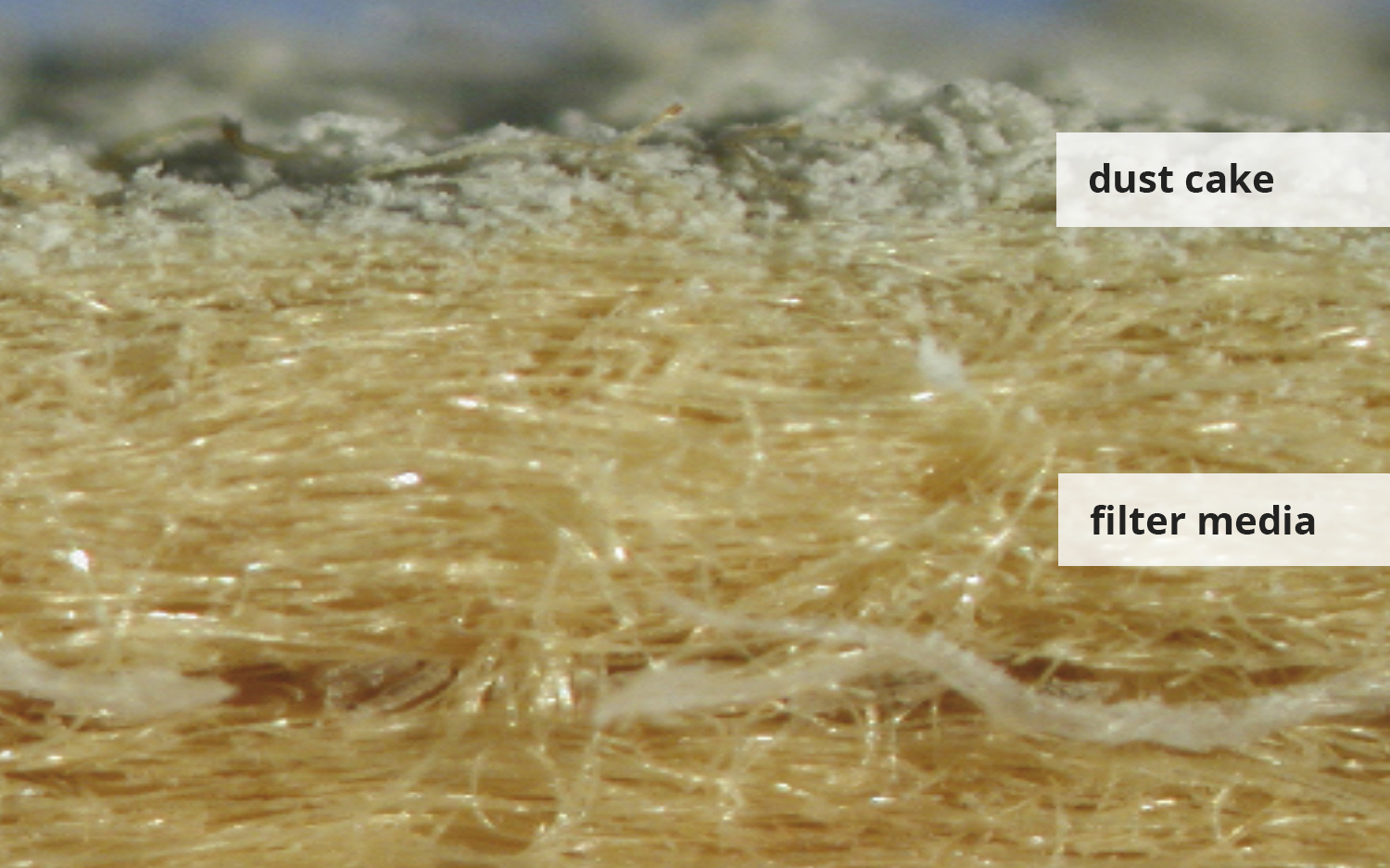

Norafin CRYSTALEN® stands for nonwovens to filter gases and liquids. We supply filter media that optimize the product lifecycle, the filtration efficiency and operating costs.

With our capability to process a variety of fibers (microfibers, PPS, aramids, polyimides...) and with our proprietary production process, our nonwovens show a consistent filter surface characterized by a higher number of finer pores and homogeneous cross-section leading to an increased filter performance.

Norafin CRYSTALEN® stands for:

The latest measurement technologies enable us to perform the necessary filter tests in-house.

During spunlacing, a homogenous, intertwined textile structure is created by means of water jets.

Compared to the traditional needlepunch technology, the hydroentanglement offers benefits that enhance the filtration efficiency.

Victoria Rößler

Sales Manager Filtration Line

| T: | +49 3733 55 07 421 | |

| M: | Victoria.Roessler@norafin.com | |

| LinkedIn profile | |

Tobias Thiem

Product Manager Filtration Line

| T: | +49 3733 5507 262 | |

| M: | Tobias.Thiem@norafin.com | |

| LinkedIn profile | |

Kevin Fiedler

Sales Manager Filtration Line

| T: | +49 3733 5507 264 | |

| M: | Kevin.Fiedler@norafin.com | |

| LinkedIn profile | |