2020

Foundation of our subsidiary Norafin Technologies GmbH for the sale of converted nonwoven products at the Mildenau site

2018

06/07/18 – Exactly one year after breaking ground, the inauguration of the US production site in Mills River, North Carolina, takes place. It is equipped with a new state-of-the-art Spunlace line and modern offices. By the end of 2018 35 new jobs developed.

2017

06/07/17 – Groundbreaking takes place for the new factory in Mills River, North Carolina.

2016

One of the leading private equity firms, VR Equitypartner, acquires 42 % of the Norafin shares. The remaining shares fall upon Maxburg Capital Partners GmbH and the Norafin management, which lay the cornerstone for further growth.

A major step for the expansion of the production capacity is sealed by the end of 2016, with the property purchased for a new production site in Mills River, North Carolina.

2014

Certified energy management system according to DIN EN ISO 50001 of Norafin Industries (Germany) GmbH

2012 - 2014

Norafin expands the production site and its headquarters in Mildenau. Through the purchase of a second spunlace line, the production capacity increases. Resulting in the formation of a new production hall, laboratory and offices.

2014 a second carding machine is integrated into the new spunlace line.

2012

Norafin becomes completely autonomous. With the help of an investment partnership with Pinova Capital GmbH. Norafin continues its successful niche strategy and stands up in the market as a supplier of high-quality nonwovens.

2009

Celebratory inauguration of the aftertreatment line.

2008

André Lang becomes CEO of Norafin.

2007

The STA Group entirely separates of Jacob Holm. The holding society changes its name from Jacob Holm & Sons STA into Vernal. The company’s headquarters are in Switzerland.

2006

The Jacob Holm group expands through the acquisition of Tytex – a leading provider in medical textiles – and Norafin becomes more independent within the organization. The sister companies Norafin and Tytex are integrated in the STA group, belonging to Jacob Holm.

2000

Integration of Norafin within the Jacob Holm group and further development of the “technical special nonwoven” division.

1998

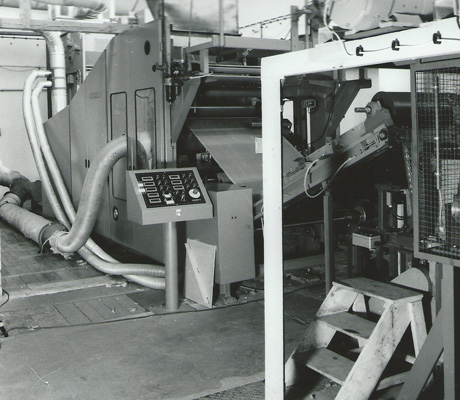

Assembling and commissioning of Norafins new spunlace line in Mildenau, Germany. The second carding machine is integrated in 1999.

1997

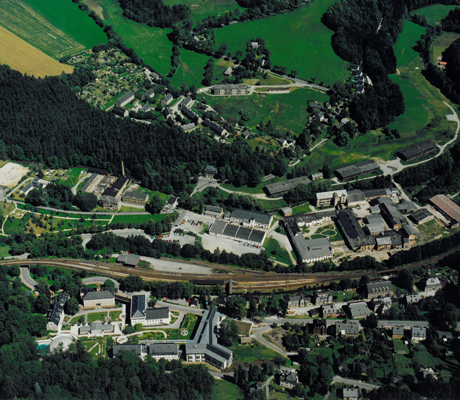

Construction of the production site in Mildenau, including the assembling and commissioning of the needlepunch line.

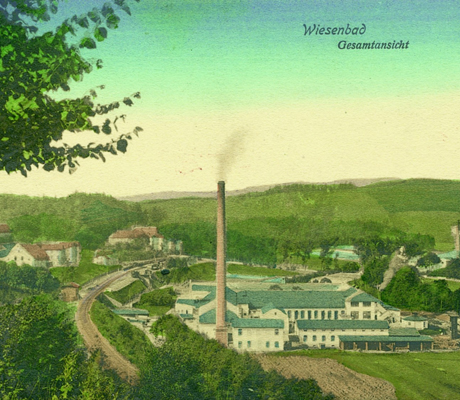

The production site in Wiesenbad is shut down by the end of 2000.

1995

Changes the name of the company to “Norafin Vliesstoff GmbH”. Production of inlay nonwovens for the apparel industry, bases for the synthetic leather industry, compresses made of viscose as well as nonwovens for the electronic industry for the insulation of motors.

1992

Privatization of the company into “Verband- und Vliesstoffe Wiesenbad GmbH”.

1985

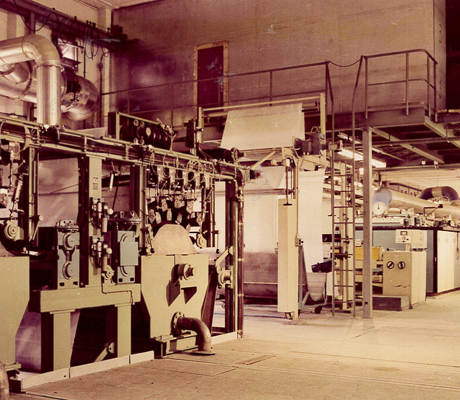

Commissioning of the FINORA-production facility as the first spunlace large-scale plant in Europe in the VEB Technotex Wiesenbad for the production of compresses and technical textiles for the synthetic leather and electrical industry. With a working width of 2200 mm, four hardening drums and 16 jetheads, a production speed of 50 meters/minute and a production capacity of 15 million square meters had been achieved.

Due to trademark concerns the project had been renamed into “NORAFIN” in the middle of the 1980s.

The term NORAFIN originates from the English term for “NOnwoven”, the Latin name for rotating water “Rotare a Aquae” as well as from the name of the ForschungsINstitut.

1983

Submission of the patent “Jetheads on a mechanism for the hydrodynamic fiber entanglement”.

The VEB Technotex Karl-Marx-Stadt, facility Wiesenbad starts with the assembling of the FINORA production line.

1980

Development of the first spunlace line in Europe, in cooperation with the Saxon research institute for textile industry (FIFT) based on the first functional model with two drums and a jethead width of 1,000 mm.

1976

Start of the development work for the “Nonwoven hardening through fiber entanglement – FINORA” in the research institute in Chemnitz. The aim was the development of a nonwoven that could be hardened hydro-dynamically without using binders or binding fibers.

1877

On March 17, J.G. Meyer from Amsterdam founds the “Mechanical Flax Spinning Mill Meyer & Co” in Wiesenbad. For more than one century, the processing of straw flax and the production of flax and tow yarns as well as linen twine and their refinement built the central point of the production.