Frank Aberle

Senior Sales Manager Cleaning Line

| T: | +49 3733 5507 225 | |

| M: | Frank.Aberle@norafin.com | |

| LinkedIn profile | |

Also in the field of personal hygiene, our nonwovens provide safety and ensure gentle & hygienic cleaning of the skin. Our nonwoven solutions form a reliable basis, e.g. for:

Whether in the home or in industry – cleanliness is important everywhere. In many areas, such as hospitality, it is required by law and it can even be a matter of life and death, for example in medicine. To ensure that you achieve exactly the required level of hygiene and cleanliness on all surfaces, we manufacture highly specialized nonwovens for you, that combine all the desired properties. With double-sided material constructions and multi-layered materials, we create multifunctional cleaning cloths for all applications. With the help of natural fibers, we can even produce sustainable cleaning cloths for you. Basis weight, dimensions, surface structures, and colors are all adjustable and can be adapted individually to your wishes and needs.

Find out about our available product modifications, contact us right away and let's talk personally for tailormade advice. We look forward to your inquiry.

For our nonwovens, we can use synthetic fibers such as polyester, recycled polyester, PLA, or botanical fibers such as viscose and lyocell. At the same time, we are able to substitute these with natural fibers with comparable performance characteristics, such as flax or hemp. Of course, blends of the different fiber types are also possible.

Our two process technologies, needlepunching and spunlacing, enable us to offer a wide spectrum of area densities to our customers in the hygiene & cleanliness sector. They range from 16 g/m² to 600 g/m² and thus cover a wide range of applications.

Only with the ideal structure for the intended use will the dirt adhere to the cloth and thus contribute to efficient, fast cleaning of surfaces or objects. Our structure portfolio ranges from smooth to fine, coarse or extra-coarse perforations, to our Norafin 3D Performance® material, an embossed nonwoven in various patterns.

Our multifunctional nonwoven combines two applications in one cloth. We combine two nonwovens with different properties using waterjet technology to create a firmly bonded special textile. For example, cleaning and polishing or greasing and abrading are done with just one cloth. The two functional layers can differ not only in terms of their structure or material, but two-color variants are also possible.

For professional and hygienic industrial cleaning, the four-color code system is part of our standard. Deviating colors are also possible on demand. Get in touch with us and let's define them in more detail in a personal conversation.

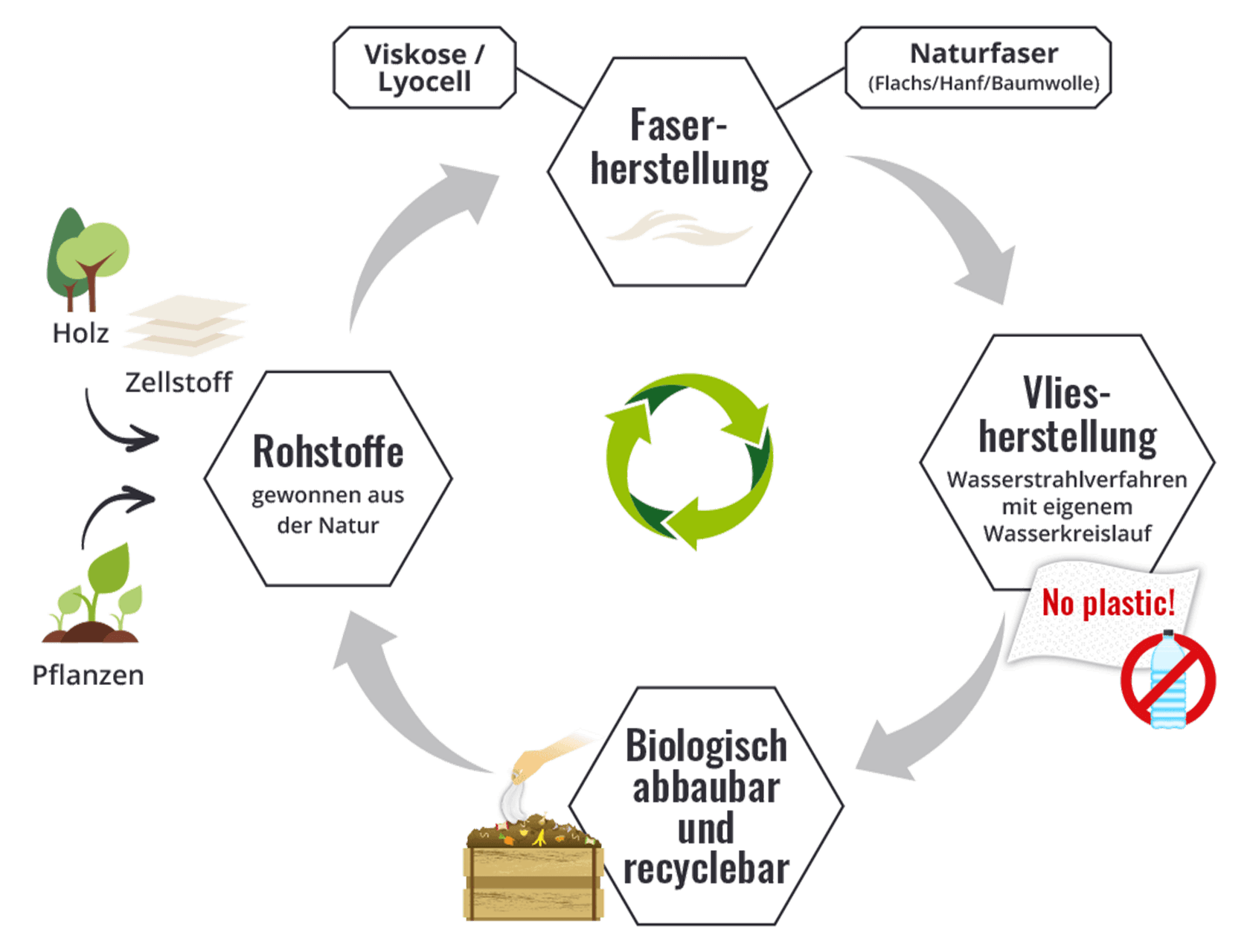

Due to the three-dimensional nonwoven layup as well as the subsequent bonding in the waterjet process, we are able to produce nonwovens made of viscose, lyocell, or natural fibers with excellent performance characteristics – and this without the admixture of synthetic fibers. Our Norafin ECOLINE® cleaning wipes can be reused several times and can be disposed of or composted in an environmentally friendly way.

Our many years of experience have led us to develop the unique Norafin KOMANDA® technology. The resulting cloth solutions have a very high tear resistance and can therefore be reused several times. In industrial washing processes, our Norafin KOMANDA® cleaning wipes have a very high resistance without loss of performance.

On our cutting machines, we can realize roll widths between 0.1 m and max. 2.4 m.

We offer in-house as well as external finishing options for the manufactured roll goods. For example, the nonwovens can be printed, coated, laminated, or impregnated.

The use of renewable or recycled raw materials is an important component for us when it comes to the sustainability of our production chain. We prefer to use VEOCEL™ fibers to support the production of biodegradable wipes.

When processing thermoplastics, we pay attention to the increased use of recycled PET fibers. An equally frequently used substitute is polylactide (PLA) fiber, a bio-based polyester fiber and frequently used as a sustainable alternative to petroleum-based fibers.

Frank Aberle

Senior Sales Manager Cleaning Line

| T: | +49 3733 5507 225 | |

| M: | Frank.Aberle@norafin.com | |

| LinkedIn profile | |

Manuel Sonnabend

Product Manager Cleaning Line

| T: | +49 3733 5507 237 |

| M: | Manuel.Sonnabend@norafin.com |